AL FARES MIDDLE EAST

AL FARES MIDDLE EAST METAL WORKS is a privately-owned business established in 2015 which specializes in metal processing company, providing:, CNC Laser cutting, CNC machining, CNC milling, CNC bending CNC punching, CNC plasma cutting, CNC turning, CNC drilling, CNC gas cutting, CNC sheet metal Works, grinding, jig boring, metal machining, steel welding....

Catalogue Read MoreAL FARES MIDDLE EAST

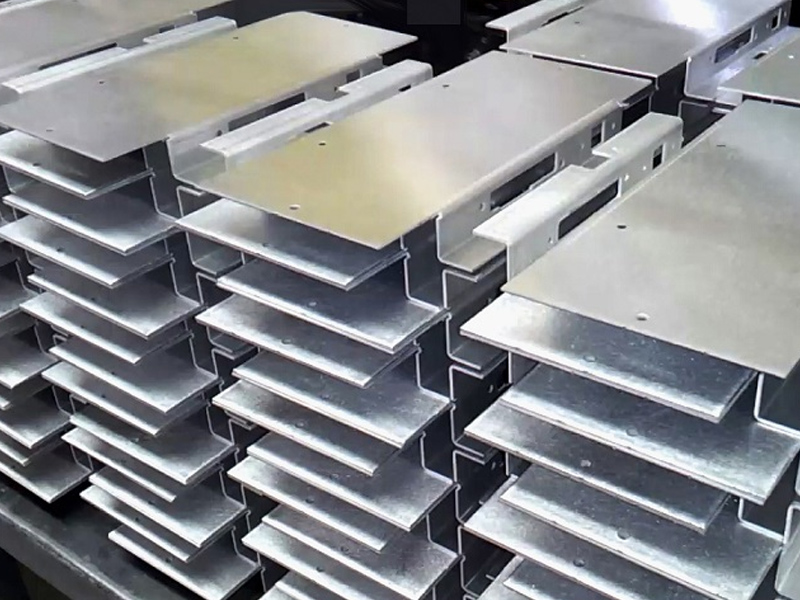

AL FARES MIDDLE EAST METAL WORKS is a privately-owned business established in 2015 which specializes in metal processing company, providing:, CNC Laser cutting, CNC machining, CNC milling, CNC bending CNC punching, CNC plasma cutting, CNC turning, CNC drilling, CNC gas cutting, CNC sheet metal Works, grinding, jig boring, metal machining, steel welding, assembling of Subassemblies, equipment manufacturing, Automotive Brackets, tool making, metal Stamping, sheet stamping (cold presswork), steel welding, stamping of details, EDM machining, electrical-discharge machining, heat treatment, stainless steel machining, non-ferrous metals machining, plastic machining, galvanic work, galvanic coatings, hot-deep galvanizing, welded structures production, powder painting, wet painting. Tools making: dies, stamps, moulds, special devices, jigs, tool parts. Welded constructions in steel, stainless steel, aluminium, building structures, production of non-standard equipment.

OUR engineers are experienced with Autocad & Solid Works while the parts are made of normal steel, aluminized, galvanized, stainless steel, aluminium and brass

AL FARES MIDDLE EAST METAL WORKS is specializes in Steel fabrication a prime manufacturer, importers and suppliers of various quality Stainless Steel and Carbon Steel, Pipe Fittings, Flanges, Fasteners, nickel alloys and special grades Round bars suitable for various applications

Based in Mussafah Industrial Area, Abu Dhabi, AL Fares Middle East Metal Works is now an industry leading sub-contract sheet metal fabrication supplier to various Metal Works sectors.

• Aerospace, Military & Defense

• Mining

• Electrical

• Contractors

• Civil Engineers

• Construction

• Private Sector

• And many more

Our Services

We Provide The Highest Quality Services

CNC Laser Cutting

CNC Laser Cutting

Precise, clean cutting and often does not require further processing. Ideal for carbon and stainless steel sheet metal, and intricate patterns. A fast, repeatable and highly accurate process which is ideal for high production runs. Not recommended for conductive materials like copper.

Technology

A computer controlled high power laser beam is focused on the workpiece and the resulting heat energy melts or vaporizes the material. Any resulting molten material is blown away by pressurized gas during the cutting process creating a high quality edge.

- Max Cut Size 5′ x 10′

- Mild Steel up to 1″ thick

- Stainless Steel up to ¾” thick

- Aluminum up to ½” thick

- Positioning accuracy +/- .002″ (relative position)

- Beam Size 1mm

- Type – CO2 (gaseous), Nd:YAG (solid state)

Specifications

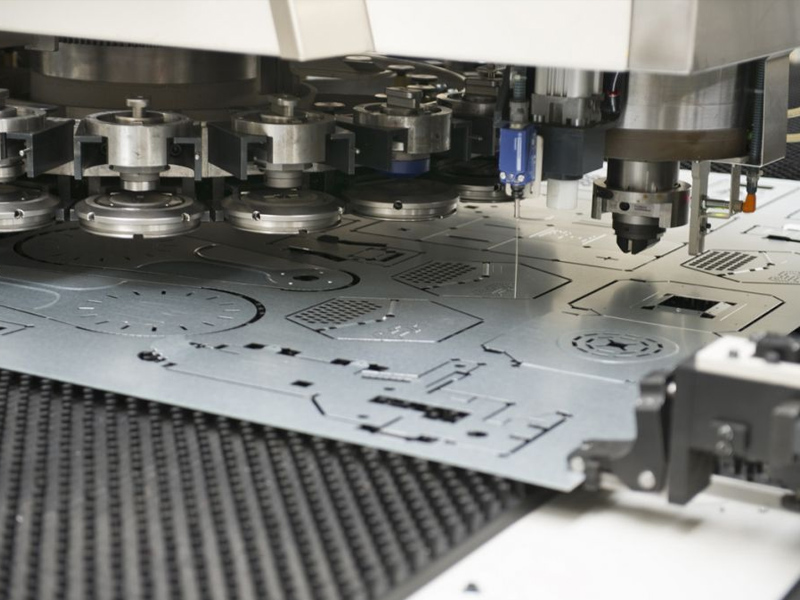

CNC Punching

CNC Punching

Our CNC punches are state of the art. Improvements in press drive technology, machine control design, tooling, and CAD/CAM programming software are increasing the throughput capability and the overall versatility of CNC turret punch press equipment in our shop.

CNC punches have high hit rates on the mechanical ram system as a direct result of the faster axis speeds and quicker acceleration and deceleration supplied by servo systems. A mechanical ram has a fixed stroke length, which starts at the fully retracted position and finishes with the ram at the exact bottom position. This type of system is simple to program and operate. This means that we can take smaller orders and be competitive in pricing as well as fulfill larger orders.

- 39″ x 60″ Sheet Size Capacity

- 5052 Aluminum: 0.032″ – 0.250″ thick

- Hot Roll Steel: Pickled & Oiled: 20 gauge – 1/4″ thick

- Galvanized: 24 gauge – 10 gauge

- A36 Steel: 0.1875″

- 304 Stainless Steel: 22 gauge – 11 gauge

- Capacity 30 Ton

Specifications

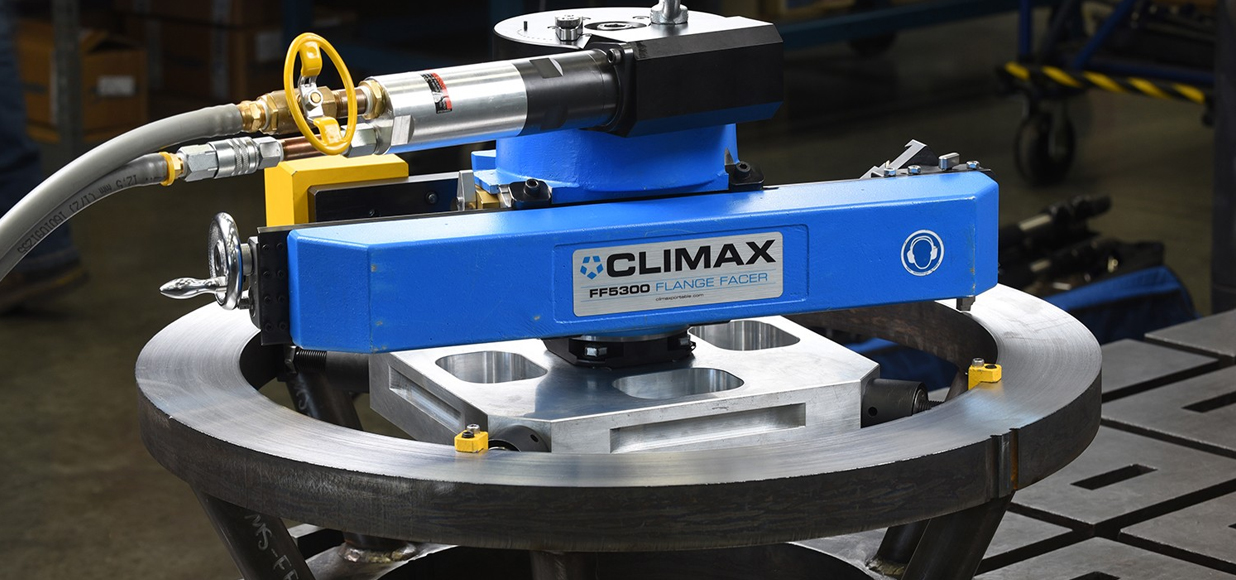

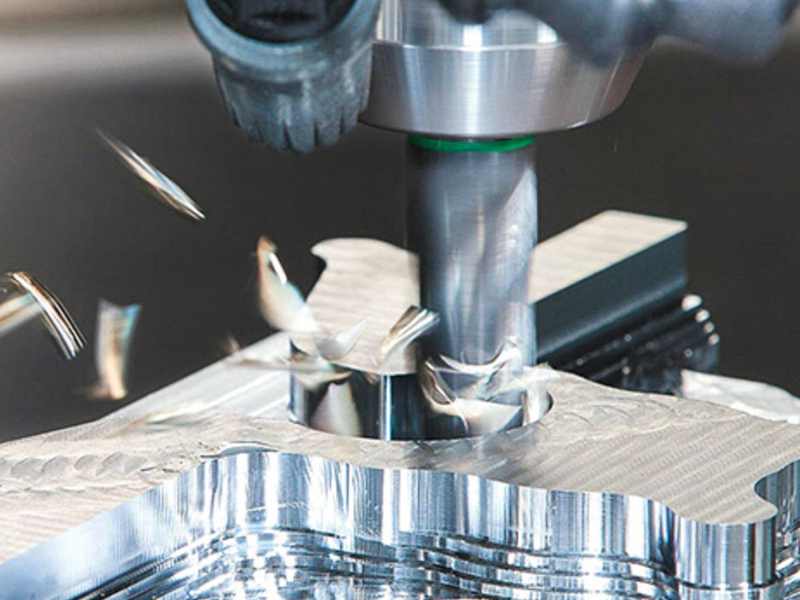

Machining

Machining

Many industries today are turning to CNC machining as a means to speed manufacturing ability and increase repeatable accuracy. The ability to machine complex shapes, undercuts and difficult angles in a single setup reduces tooling cost and labor time, resulting in a better cost per part in addition to maintaining parts conformity throughout the run of the part.

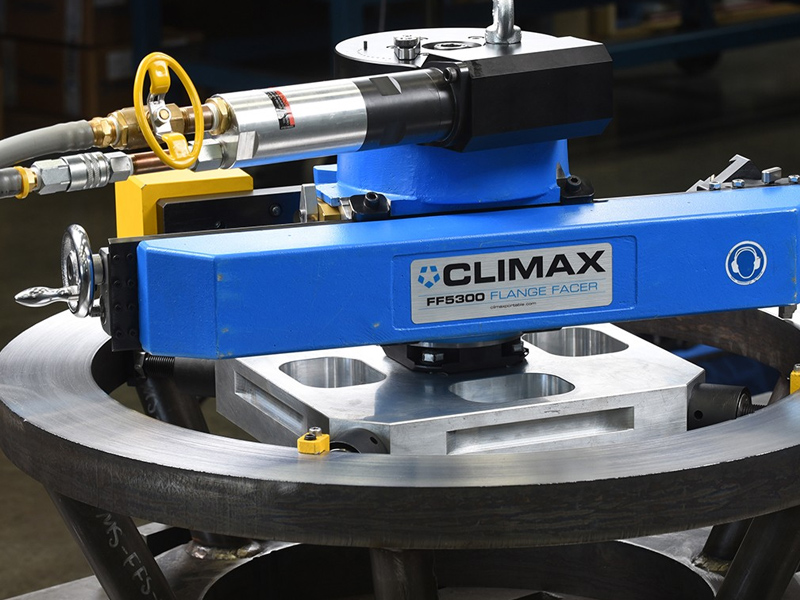

Portable Machining

Millwright Services

Welding & Fabrications

High-Quality Contract Welding Services

High-Quality Contract Welding Services

What are you looking for in your contractor? If you need something specific that fits well with your existing solution, you need a sheet metal fabricator that has the range to deliver what you’re looking for. Al Fares offers a number of solutions that cater to your exact needs. From contract manufacturing to developing prototypes, we offer a unique skill set that reflects our industry experience. Whether you need heavy or smaller components, our welding services are exactly what you’ve been looking for.

Services We Offer

How many welding service providers can deliver everything you’re looking for? From the unique materials we work with (including aluminum, stainless steel, and more) to the welding techniques we incorporate into our operations, Al Fares can do it all. Our services include:

MIG (Metal Inert Gas Welding)

MIG welding, also known as GAS Metal Arc Welding (GMAW) uses a wire electrode that’s fed through a welding gun. By incorporating an inert gas and spraying it over the welding puddle, the product is protected from contamination. It’s widely acknowledged as one of the most common methods because of its versatility and ease of use.

Services We Offer

How many welding service providers can deliver everything you’re looking for? From the unique materials we work with (including aluminum, stainless steel, and more) to the welding techniques we incorporate into our operations, Al Fares can do it all. Our services include:

TIG (Tungsten Inert Gas Welding)

Also known as Gas Tungsten Arc Welding, TIG Welding uses a non-consumable tungsten electrode to run a current through the metals being joined. A filler metal may or may not be used.

FCAW (Flux-Cored Arc Welding)

Similar to MIG Welding, FCAW methods feature a flux-filled tubular wire. The flux protects the welding puddle from contamination. Alternatively, a shielding gas can be used.

SMAW (Shielded Metal Arc Welding)

Also known as “stick” welding, SMAW welding solutions refer to an electrode coated in a protectant flux. An electric arc is created by direct (or alternating) currents, which results in the electrode melting and joining the metals. The flux coating creates a shielded environment to protect the weld area.

Fabrication In Steel

Powder Coating & Painting

Powder Coating & Painting

we provide quality service from start to finish for every project. Our powder coating services offer a high-quality, efficient solution for the coating process. With no need for expensive pollution control equipment due to the lack of solvents, you’ll enjoy superior coating at a reasonable price.

Precision Powder Coating Services

For the team here at Al Fares, the proof is in the process. Our powder coating system is the result of countless hours of fine-tuning and training—we’ve worked every angle to make sure our service is light years ahead of conventional paint jobs and other powdered spray solutions. We’ve powder-coated aluminum, stainless steel, and carbon steel materials and can customize our process to meet your unique needs.

Services We Offer

How many welding service providers can deliver everything you’re looking for? From the unique materials we work with (including aluminum, stainless steel, and more) to the welding techniques we incorporate into our operations, Al Fares can do it all. Our services include:

Pre-Treatment

Our pre-treatment phase includes media blasting and a five-stage wash system, creating superior performance and an increased lifespan for the final product. After we dry the material and preheat the parts, they’re ready for powder coat application. We emphasize the importance of setting up everything correctly right from the beginning, so there are never surprises down the road.

Services We Offer

How many welding service providers can deliver everything you’re looking for? From the unique materials we work with (including aluminum, stainless steel, and more) to the welding techniques we incorporate into our operations, Al Fares can do it all. Our services include:

Color Choices

No need to stick with a one-size-fits-all solution—the color you ultimately choose should reflect what you had in mind for your product before the process began. We offer our customers several color options for their powder coat.

Finishing Touches

Once the powder coat is on the material, we heat the section at a temperature and duration based on the chemistry of the powder and density of the coat. This successfully melts and fuses the powder for a finish that will continue to look great long after it’s delivered to your customers.

IN-HOUSE FINISHING & ASSEMBLY

IN-HOUSE FINISHING & ASSEMBLY

We does all of its domestic manufacturing, finishing and assembly in-house. Our in-house powder and liquid coating lines allow us to manufacture your parts from start to finish. Our five stage in-line pretreatment system assures a long-lasting durable finish on your products.

CNC METAL BENDING

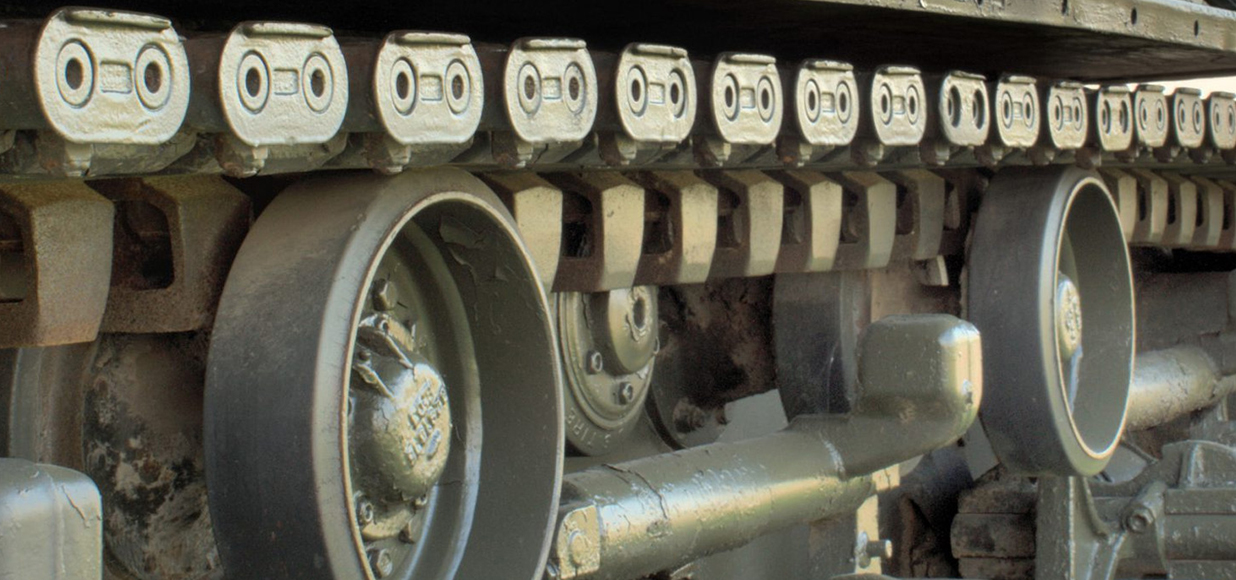

METAL FABRICATION FOR THE MILITARY AND DEFENSE INDUSTRY

METAL FABRICATION FOR THE MILITARY AND DEFENSE INDUSTRY

Our capabilities include CNC Machining, Fabrication, Laser, multi-axis machining, mechanical and electrical assembly, water jet cutting, Press Brake, MIG Welding, TIG welding, blasting & Painting as per Military required specification.

We specialize in Designing and fabricating components for the defense industry is a high-risk endeavor, and our clients trust that we will find their custom solution while keeping costs to a minimum and following the highest quality standards. We also understand the rigorous standards and deadlines that must be met when manufacturing within this sphere.

We also specialized in welding services for the defense industry. It assures optimum weld quality and validates the capability and repeatability of a resistance welding machine used in a welding process where weld quality is crucial in the manufacturing of critical parts, as in the defense and aerospace industries.

Our partners in the military sector choose us for our expertise in sheet metal fabrication and MIG / TIG welding. Our highly trained staff of engineers, machinists, Painters and welders work diligently from project start to finish to bring each of our clients the best possible final product

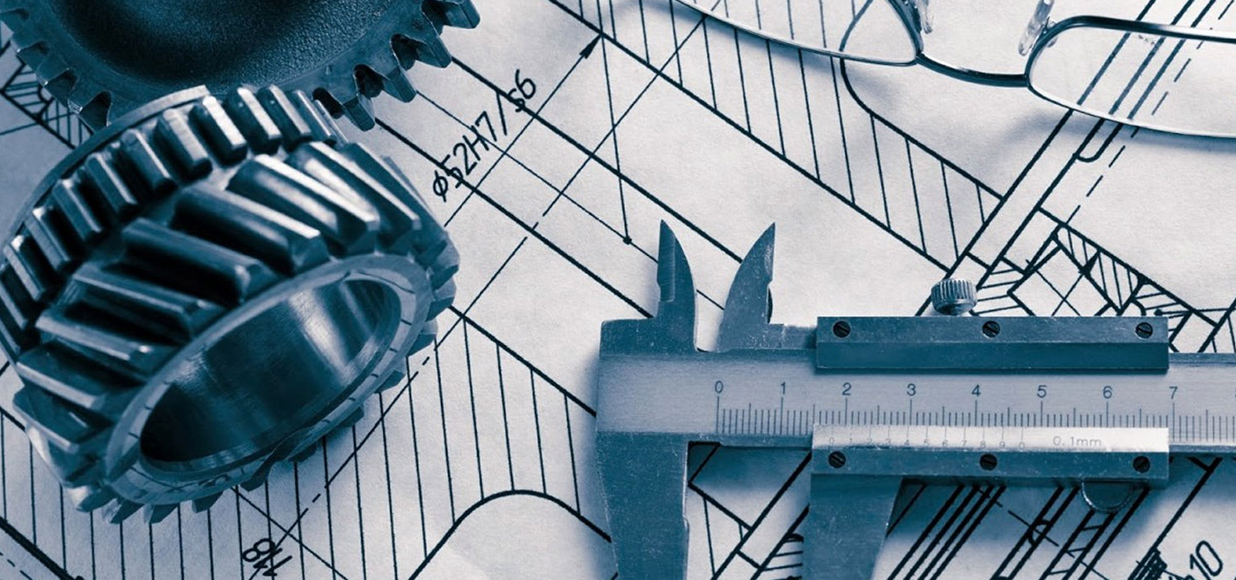

Design Engineering

Design Engineering

Products are skillfully engineered using state-of-the art CAD software.

Three-dimensional scale CAD models of the physical part or product assembly are created which allow our customers to analyze the functionality of the product, provide a simple visualization and ultimately eliminate any product design errors early in design phase. Up front expert analysis of the design ensures a cost effective manufacturing, assembly and production method is achieved. These 3D product designs can therefore be approved by our customers before starting the prototype manufacturing process.

All products are professionally designed to minimize manufacturing costs, while considering looks, functionality and durability.

Creating a prototype product or "pre-production" presentation of your idea offers the following major advantages:

- It enables you to test and refine the functionality of your design. Sure, your idea works perfectly in theory but it's not until you start physically creating it that you'll encounter flaws in your thinking. Developing a prototype will allow you to test the functionality of your idea. You'll never know the design issues and challenges you are going to face until you begin actually taking your idea from theory to reality.

- It makes it possible to test the performance of various materials. For example, your heart may be set on using metal--until you test it and realize that, say, plastic performs better at a lower cost for your particular application. The prototype stage will help you determine the best materials.

- It'll help you describe your product more effectively with your team, including your attorney, packaging or marketing expert, engineers and potential business partners.

- It will encourage others to take you more seriously. When you arrive with a prototype in hand to meet your own attorney or potential licensing company, you will separate yourself from the dozens of others who have approached them with only an idea in mind. Instead, you'll be viewed as a professional with a purpose, as opposed to just an inventor with a potentially good idea.

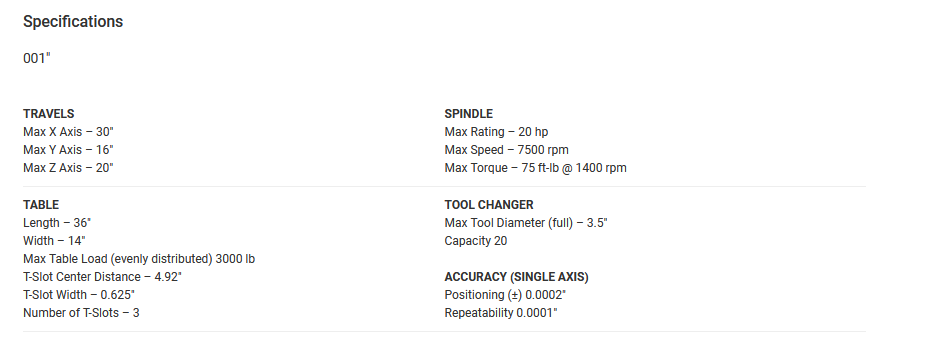

Specifications

Our Products

Stainless Steel Turned Parts

Stainless Steel Turned Parts

We like to work with the material in stainless steel grade. We produced high precision machine parts in all the grades for stainless steel like 304,316. While machining this products we keep keen attention over deburring and specified tolerances.

Mild Steel Turned Parts

Mild Steel Turned Parts

We are specialized in manufacturing of Mild Steel Parts in designs. We have strong command in machining of this material as well as its variant grade like EN series. While machining we keep our specified tolerance to achieve the final size easily.

Aluminium Turned Parts

Aluminium Turned Parts

We have developed the unique machining process for this range of material. Mostly this range is required in Lighting Industries and Architectural interior/ exterior products. We give an attractive look for these parts after plating / anodizing.

Brass Turned Parts

Brass Turned Parts

We mostly supply this product to Gas Industry, Chemical Industry, Air Pneumatic works, Electrical / Cable works and Fluid Industries. We also manufacture brass fittings for hardware products and no bar for material grade.

Copper Turned Parts

Copper Turned Parts

These are mostly in different nozzles, guns, jet, plasma manufacturing. We are familiar with all copper electrode grade materials. These are useful in gas, plasma industries, and nozzles. Mostly applicable in high heat dissipation area.

MACHINES ENGINEERING

CONTAINER ENGINEERING

DEFENCE VEHICLE

MEASURING TECHNOLOGY

CONVEYORS

CRANE ENGINEERING

COOLING SYSTEMS

AGRICULTURAL MACHINERY

FOOD INDUSTRY

LOGISTICS (RACKING)

MECHANICAL ENGINEERING

PLANT CONSTRUCTION

LABORATORY TECHNOLOGY

WAGON ENGINEERING

Contact Us